17 May 2022

3D printing filaments: ABS

3D ABS filaments have become very popular in recent years, thanks to their versatility, strength and heat resistance. These 3D printing filaments are widely used for the production of industrial parts, prototypes and functional models. In this article, we’ll explore in depth the general characteristics of 3D ABS filaments, what we offer at LATTICE SERVICES, examples of applications we have as well as an alternative to ABS.

Some general information on ABS

ABS 3D printing filaments are one of the most commonly used materials in 3D printing. ABS, short for Acrylonitrile Butadiene Styrene, is a high-strength polymer offering excellent resistance to impact, heat and corrosion. It is widely used in the manufacture of toys (e.g. Lego building bricks), pipes, mechanical parts, plates and cutlery in the fast-food industry.

ABS was one of the first materials to be used in 3D printing. It is one of the founding pillars along with PLA.

As one of the most versatile and affordable materials, ABS is popular on the 3D printing market. Its popularity is also due to its smooth, glossy finish, which gives printed objects a professional look. What’s more, ABS is very easy to handle, enabling a wide variety of designs.

However, printing with ABS filaments can be a little trickier than with other materials. The filament must be heated to a relatively high temperature before it can be extruded, usually around 230°C. It is also important to set the print bed correctly to avoid distortion. Without a hitch It is therefore recommended to use a 3D printer equipped with a heated bed for better filament adhesion.

Our printing recommendations

As ABS is a polymer that shrinks on contact with air, it is prone to warping. If you wish to print on ABS, we recommend that you use a heated tray and add a border when slicing, to help prevent warping.

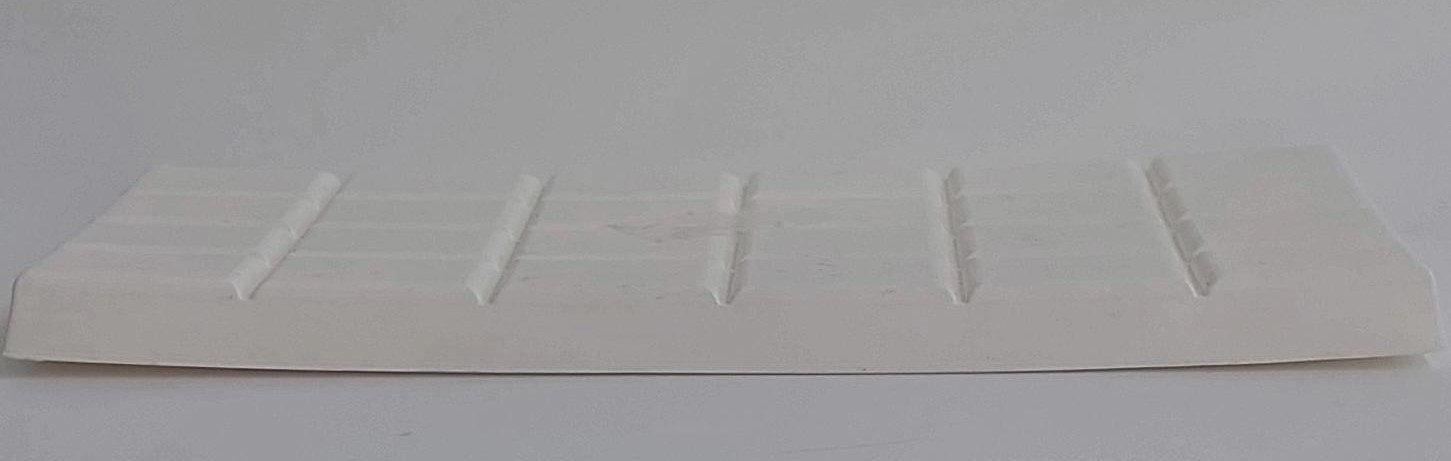

An exaggerated example of warping with ABS:

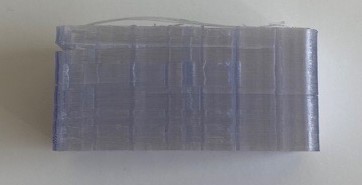

3D ABS filament also suffers from delamination. This occurs when the printed layers don’t adhere properly to each other (due to temperature or draughts), creating a separation between the two layers. To avoid delamination of 3D filament, we recommend using a heated bed at a temperature of around 110° for best adhesion. The nozzle temperature needs to be around 240°C for the ABS filament to melt properly and not delaminate. Finally, we advise you to use a lower printing speed for better adhesion, and not to overtighten the pressure screw to prevent the filament from warping.

To avoid warping, we recommend that you cool the filament gently.

An exaggerated example of delamination with PC:

ABS also has certain disadvantages. During printing, it emits a strong, unpleasant odor due to styrene, so it’s advisable to print in a well-ventilated area. What’s more, like most filaments apart from elastomers, it is sensitive to humidity, which can affect print quality. We recommend storing ABS in an airtight bag with a sachet of silica gel to keep it dry.

What we offer at Lattice Services

At Lattice Services, we offer ABS filament, an ivory-colored amorphous polymer that is rigid and durable.

Our ABS spools are available in two different diameters, 1.75mm and 2.85mm, and are packaged in 500g spools. Thanks to its ISO 10993-5 certification for skin contact and food contact, our ABS filament is perfectly suited to the production of medical or food-related parts in 3D printing.

You can sterilize our 3D printing filaments using the ethylene oxide sterilization method.

With Lattice Services, you can be sure of the quality of our products and their compliance with the most stringent health and safety requirements.

Our Uses Cases

Orthosis

Surgical model

An alternative to ABS

There’s an interesting alternative to ABS: the PET-G.

This material offers good mechanical and thermal resistance, making it a quality choice for many 3D printing projects. What’s more, it’s easier to print than ABS, which greatly facilitates the printing process.

Still, it’s essential to consider the properties and characteristics of each material, such as its strength, flexibility, durability and ability to withstand specific conditions. Taking these factors into account can help ensure that the chosen material is ideally suited to the task in hand.

In conclusion, ABS 3D printing filaments are a popular choice for professionals and hobbyists alike, thanks to their strength and smooth post-processing ability to be smoothed with acetone. Although they have certain disadvantages, printing with ABS can be very rewarding for those seeking to create professional, high-quality designs.