LATTICE SERVICES was born from the expertise of LATTICE MEDICAL

In 2020, LATTICE MEDICAL decides to create a new entity with LATTICE SERVICES. LATTICE SERVICES brings its know-how dedicated for the design, production and commercialization of medical grade 3D printing filaments for the development of innovative implants from tissue engineering.

Disruptive technologies to create the solutions of tomorrow.

LATTICE SERVICES provides its own procedures for research teams

We are specialized in polymer-based tissue engineering projects and implantable medical devices. For this, we have developed different types of 3D printing filaments using medical polymers with the aim of providing the best performance.

These absorbable and implantable filaments are manufactured in our facility.

LATTICE SERVICES cultivates competence and versatility

Our value chain allows us to answer to the needs of research laboratories, medical device companies, FabLabs which would like to integrate additive manufacturing into their project.

LATTICE SERVICES also produces filaments according to your specifications

Our team offers its know-how to make your own custom-made polymer extrusions and supports you in the success of your 3D prints using our customization service.

Our services

Filament

3D printing

and prototyping

Material

characterization

LATTICE over the years

- 2017 “Ruban Rose” winner

- 5 employees

- Start of incubation at Eurasanté

- Creation of the company LATTICE MEDICAL

- Fundraising of 2.3 million euros from investment firms

- 2018 “i-Lab” laureate

- Exclusive licensee of MATTISSE technology

- 8 employees

- New 300 m² offices (3D printing, materials, cell biology)

- Design Freeze and Process Freeze of the MATTISSE implant

- 12 employees

- Commercialization of our first sets of medical filaments for 3D printing

- I-Nov 2020 laureate

- Establishment of a partnership with the company Cousin Biotech for the installation of a 3D printing farm in a clean room to produce medical devices

- Launch of the Lattice Services branch, dedicated to 3D printing for the medical device sector

- Design and Process Freeze of the MATTISSE prosthesis

- Start of production

- France Relance and EIC Accelerator award winner

- Extension of premises: Acquisition of an additional 243m².

- 17 employees

- 2nd Fundraising

- Start of our clinical trials

- Application of the Year Award by ADDITIV MEDICAL

- Clinical investigation opens at Lille University Hospital, then at Strasbourg University Hospital

- Winner of FrenchTech 2030 in June

- Nominated for the Prix Galien USA in July

- Secured €6 million in funding under the France 2030 plan in January

Breast reconstruction at the heart of LATTICE MEDICAL’s advances

LATTICE MEDICAL is a biomedical company that combines tissue engineering and 3D printing. Founded in 2017 from the experience of engineers and surgeons passionate about new technologies.

It dedicates it know-how to breast reconstruction, particularly following breast cancer. This affects 1 in 8 women in the world. And in 40% of cases, the usual treatment is a mastectomy followed by chemotherapy or radiotherapy. Only 17.5% of women undergo reconstructive surgery afterwards. This observation is explained by the fact that the current solutions are few (silicone breast implants, adipose flap surgeries or fat grafting …). In addition, the path to restorative reconstruction is long and can be painful for women who have experienced trauma. It requires and can generate:

heavy and numerous surgeries

complications that can be significant

costs related to the health system, making procedures long and complicated for patients

A unique and gathering project!

This is why LATTICE MEDICAL has been engaged for several years – with the support of the Lille University Hospital – in research in order to offer a new alternative to these different existing methods. Our goal was to find an innovative solution combining the advantages of current techniques while simplifying breast reconstruction procedures in order to make it less expensive and more accessible to all.

MATTISSE an implant resulting from our exclusive technologies

We have implemented a new bioabsorbable tissue expansion implant called “MATTISSE” using our 3D printing techniques. The principle is to use autologous adipose tissue collected near the breast area during surgery and combine them with a resorbable porous 3D printed base that will help regenerate adipose tissue. This implant is custom-made in order to achieve the desired size in one surgery. MATTISSE implant is composed of 2 parts:

A porous base improving fat regeneration

A shell giving the desired volume and shape

This shell is made using our medical grade resorbable polymers, which are made into 3D printing filaments. The use of 3D printing allows, using MRI or CT-scan images, to design a personalized implant to restore the removed breast. It takes 3 to 6 months for the fatty tissue to be fully restored. And 18 months for the complete resorption of the implant. The breast is therefore entirely reconstructed by the patient’s own tissues, without any foreign body.

Our Means for Tissue Engineering

Our production tools to design prototypes

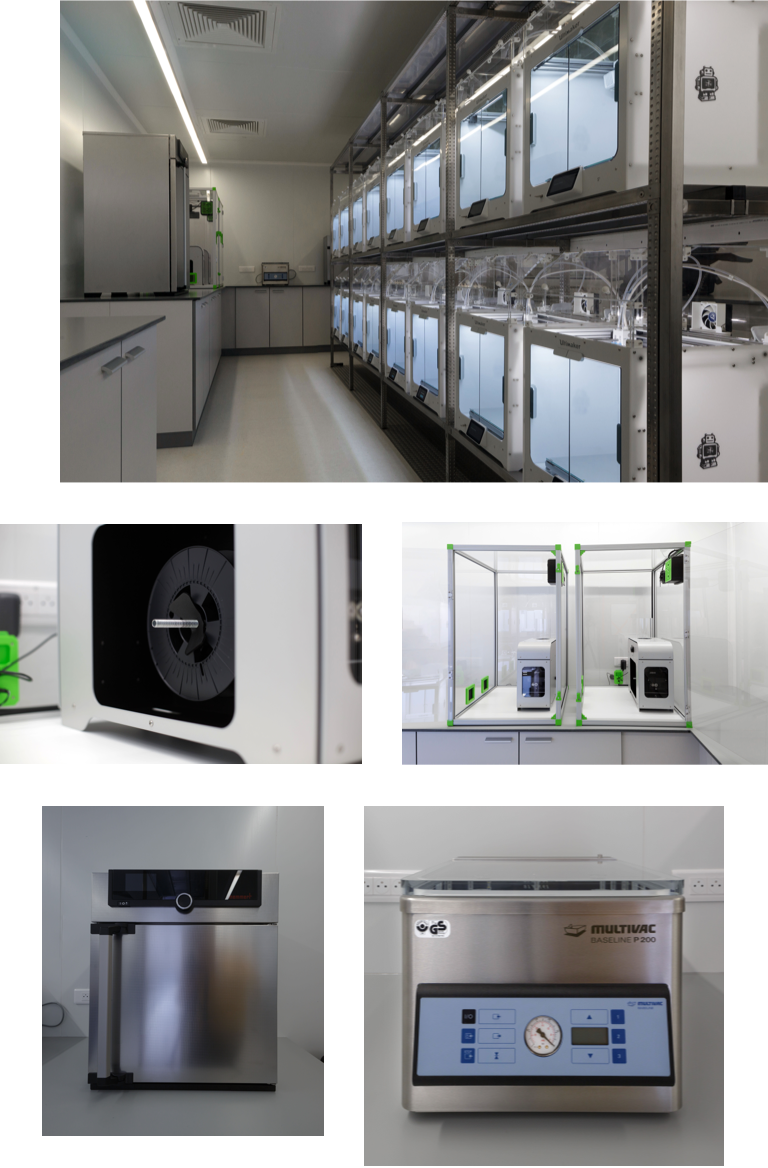

In order to produce reliable prototypes and pre-series, LATTICE SERVICES sets up an ISO7 certified clean room and a research laboratory, which gather all the equipment necessary for the production of filaments and medical devices.

Turn your ideas into a real product

Our 3D printing farms is made up of 35 machines, including 16 3D printers and 2 extruders for our clean room and 12 3D printers and 5 extruders for our laboratory.

For this, we use Fused Deposition Modelling (FDM) and Pellet Additive Manufacturing (PAM) technologies, which use the technique of molden filament deposition by applying it layer by layer.

Our machines allow the use of 1.75- and 2.85-mm diameter filaments. These machines are equipped with 0.2 or 0.4mm diameter nozzles and can print different layer heights, typically 0.1 or 0.2mm or even less for some applications.

Our analytical tools

LATTICE SERVICES has an analytical laboratory in order to characterize your products and specifications.

The lab offers mechanical test benches to provide different material properties such as Young’s modulus, elongation at break, maximum stress and stress at break.

Moreover, we have a gel permeation chromatography (GPC : Gel Permeation Chromatography ) which allows measurement of polymer molecular weight, as well as their distribution.

Our research laboratory also includes a differential scanning calorimeter (DSC : Differential Scanning Calorimetry), which measures the various thermal events that polymers undergo. This allows us to control the shaping processes of our polymers.

Finally, we have a cellular biology lab used to run in vitro experiment in order to ensure cells viability onto materials and degradation properties of polymers and products.All our machines are qualified and have regular maintenance to ensure the reliability and reproducibility of the results.

Meet our team

LATTICE SERVICES is above all a team of multidisciplinary experts, determined and passionate, applying their expertise to meet the challenges of tomorrow.

Our experience and our varied profiles have allowed us to develop an increased sense of listening in order to turn each future project into a concrete product.