3D printing services

We implement all your product development projects, from design to prototyping and pre-production, thanks to our 3D printing capabilities and our expertise in medical projects.

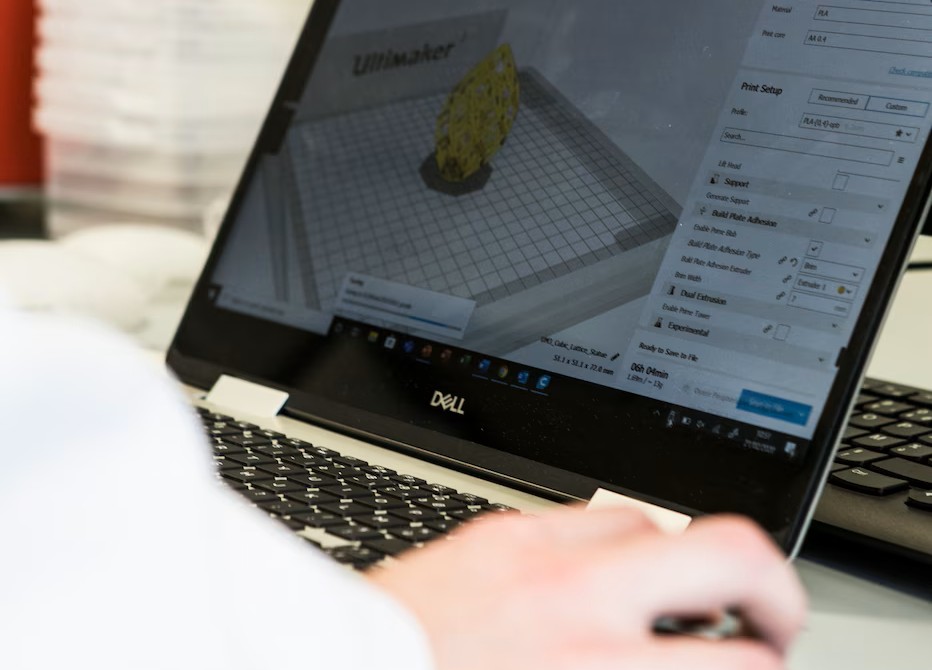

Bring your ideas to life with our state-of-the-art computer tools. Our computers are equipped with advanced modeling software such as SolidWorks, enabling precise and efficient design of your prototypes. What’s more, with simulation software such as Abacus, we carry out in-depth analyses to ensure the reliability and performance of your creations. With these resources at our disposal, we can offer you innovative, high-quality prototyping solutions.

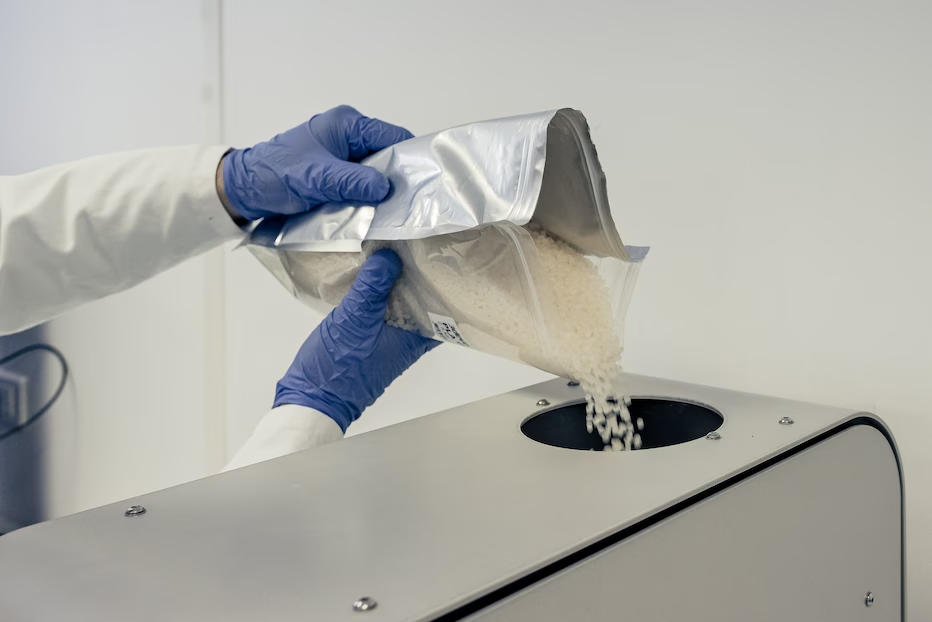

Create customized 3D printing filaments with LATTICE SERVICES polymers or your own materials. Customize your product by adjusting the diameter from 0.8 mm to 3 mm and incorporating unique functional properties, such as antibacterial, conductive or cell regeneration capabilities. Transform your projects with our flexibility and expertise in advanced materials.

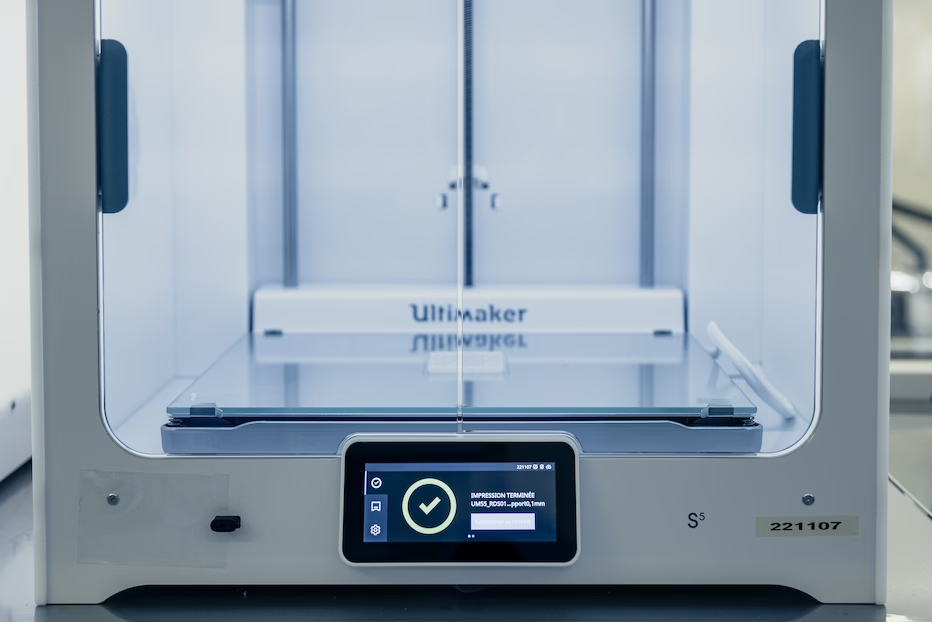

Our company offers 3D printing services with several advanced technologies. We can produce your parts using FDM (Fused Deposition Modeling) printing, which offers great versatility and rapid production using a variety of thermoplastic materials.

We also have machines for SLA (stereolithography) printing, which uses photopolymer resins to produce high-precision parts with fine detail, ideal for applications requiring excellent resolution.

Finally, SLS (Selective Laser Sintering) technology can also be used. This technique uses thermoplastic powders to create complex, resistant and functional parts, without the need for supports.

LATTICE SERVICES has a biology laboratory on its premises.

We have a range of equipment including

A screening platform to characterize your implant or biomaterial by performing in vitro tests (resorption tests, cytotoxicity tests, tests to assess the impact of the material/implant on cell differentiation and tests to assess the impact of the material/implant on vascularization).

Simulate a resorption study: simulate and observe the behavior and degradation of your material. This analysis enables you to assess the durability, performance and longevity of the biomaterial under real conditions of use (depending on your design, these properties may vary).

Finally, we offer accelerated ageing studies that give you an idea of the resorption of your part and, once correlated with conventional ageing, will save you time on your studies.

All our machines are qualified and regularly maintained to ensure reliability and reproducibility of results.

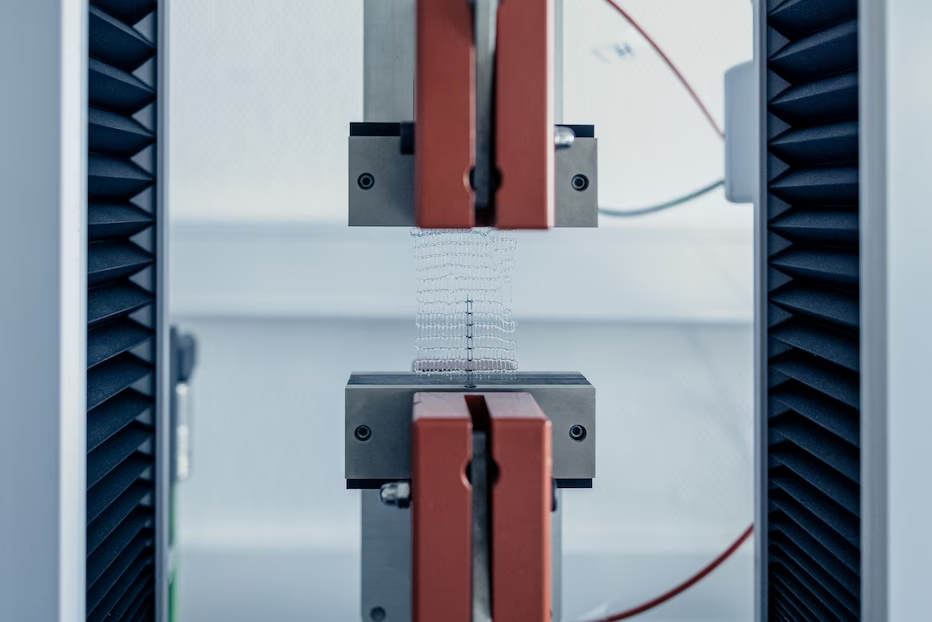

Our laboratories are fully equipped for in-depth materials analysis. Thanks to our facilities, we can provide you with precise, reliable data on the properties of your materials, to help you optimize your products. We have :

A mechanical test bench, enabling us to carry out tensile or compression tests and thus provide various material properties such as Young’s modulus, elongation at break, maximum stress and stress at break.

A Gel Permeation Chromatography (GPC) system to measure polymer molecular weight and distribution.

A Differential Scanning Calorimeter (DSC), to measure the various thermal events undergone by the material. This enables us to control our polymer shaping processes.

All our machines are qualified and regularly maintained to ensure reliability and reproducibility of results.