TPE: 3D Printing Filament

16 May 2024

Focus on TPE

In this guide, we’ll explore the TPE in detail, with general information, printing tips, a presentation of our services and concrete examples of use.

In addition, you can find an infographic on the subject available on our social networks.

First of all, what is the TPE?

TPE is the abbreviation for ‘thermoplastic elastomer’, a thermoplastic rubber with thermoplastic and elastomeric properties, combining the characteristics of rubber and plastic. It is highly prized for its flexibility. This means that any rubbing against the skin will not cause irritation, making it suitable for a wide range of applications.

Some general information about the TPE

Elastomeric thermoplastic is a white thermoplastic. With a glass transition temperature below room temperature, this thermoplastic is valued for its flexibility and high impact resistance. The TPE filament is made from granules that comply with ISO 10993-5 certification, enabling applications in contact with the skin such as orthopaedic devices and flexible contact parts interfacing with the rigid parts of orthoses or prostheses.

Key features of the TPE

- Extremely flexible

- Highly resistant to impact and fluids

Our 3D printing tips for TPE

For best results with TPE, follow our printing advice:

- Extrusion temperature: Set the extrusion temperature between 220°C and 240°C, according to the manufacturer’s specifications.

- Print platen: Use a heated platen between 40°C and 60°C.

- Print speed: Choose a moderate speed, generally between 10 mm/s and 40 mm/s.

- Cooling: Minimise cooling to maintain material flexibility.

- Retraction: Set shrinkage parameters correctly to avoid burrs.

What we offer at Lattice Services

At Lattice Services, we offer you medical grade TPE filaments, flexible and biocompatible, available in 1.75 mm or 2.85 mm spools, weighing 500g. The price is €99.90 incl. VAT (€83.25 excl. VAT) per spool.

Our Use Cases

The TPE has a wide range of applications in various sectors. Here are a few examples:

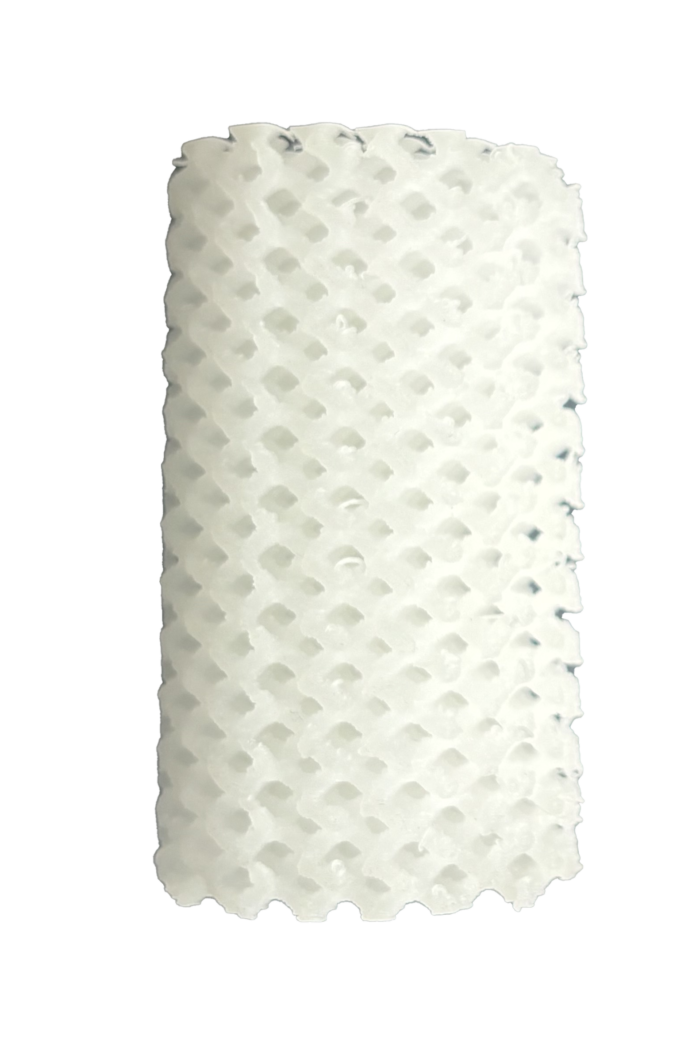

- Lattice structure: A lattice structure is a three-dimensional network of geometric shapes, such as lattices or nodes, that forms a light, strong structure. In 3D printing, these structures are created layer by layer, enabling the manufacture of complex parts with reduced weight while retaining their strength.

- Bicycle handle: Although TPE filament is mainly used for medical applications thanks to its biocompatibility and flexibility, it can also be used for non-medical products such as bicycle handles. It provides comfort and grip, good impact resistance and durability.

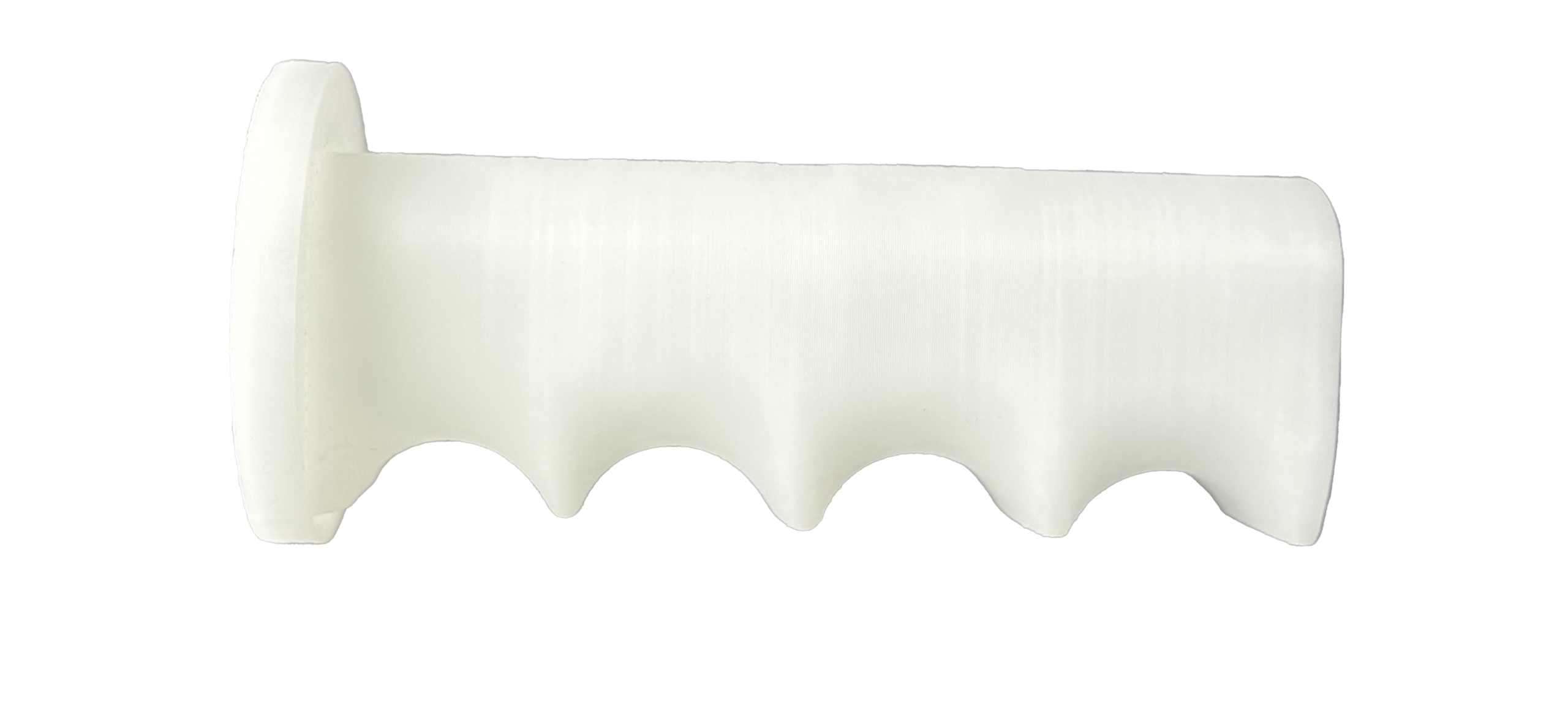

- Endobronchial incubation probe: Thermoplastic elastomer filament is an excellent choice for making endobronchial intubation probes, thanks in particular to its flexibility. This flexibility allows the probe to easily follow the curves of the airways without the risk of damaging them or causing irritation.