Our client

The Ohio State University is a renowned public research university located in Columbus, Ohio, United States, known for its emphasis on scientific innovation and interdisciplinary research. With expertise spanning health sciences, engineering, environmental studies and many other fields, it encourages cutting-edge research and collaborative projects, making it a strategic partner for organisations seeking effective scientific solutions.

Their need

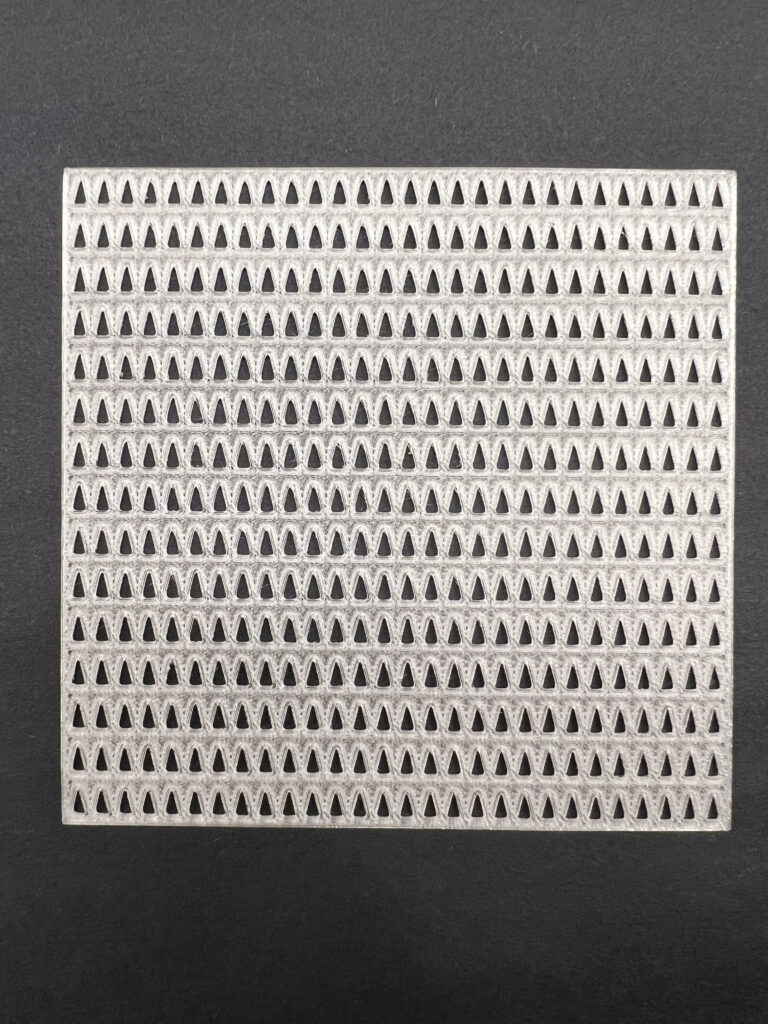

The Ohio State University is currently developing a radiopaque, biodegradable mesh intended for implantation after breast tumour resection during a lumpectomy. This mesh is designed to mark the tumour cavity and optimise post-operative radiation targeting.

The team required a material that was:

- Biocompatible and implantable,

- Flexible with a glass transition temperature (Tg) close to room temperature,

- Highly reliable for 3D printing,

- Bioresorbable in 12 to 24 months,

- Sufficiently homogeneous to serve as a baseline reference when comparing other PLCL blend formulations.

Our solution

Lattice Services has introduced its medical-grade PLCL 70:30 filament, a semi-crystalline, semi-transparent copolymer composed of L-lactide (70%) and ε-caprolactone (30%). This material offers high flexibility, stable printability and controlled resorption over a period of 12 to 24 months. Supplied in 1.75 or 2.85 mm spools (100 to 200 g), the filament is produced in France under controlled conditions.

We use Lattice 70:30 filament as our reference PLCL. This filament is incredibly easy to use. We have not encountered any printing issues, thanks to the accuracy of the recommended settings.

Adrian Bakhtar, PhD candidate, The Ohio State University

Our filament

Our PLCL 70:30 offers:

- Ionic compatibility and bioresorbability (12 to 24 months)

- High flexibility thanks to a Tg close to room temperature

- Uniform diameter and excellent 3D printability

- Flexible and transparent appearance

- Ideal for implantable meshes, nerve guides and soft tissue scaffolds

To maintain its performance, the material must be stored in a vacuum with a desiccant, away from light, and kept between –4 °C and –20 °C.

Need some help?

Our team has great experience in PLCL processing and the development of medical-grade filaments. We help our customers optimise their parameters, printing strategies and material choices to ensure consistent, high-quality implant production.