31 January 2024

Newsletter #1 : Discover the PCL 100

Our Absorbable and Implantable Filaments and our New Gem : the PCL 100

The PDO 100 Filament

PDO or Polydioxanone is a white semi-crystalline thermoplastic. It degrades quickly once implanted in 4 to 6 months. Although very crystalline, the polymer has a lower glass transition temperature than room temperature, which guarantees a certain flexibility.

👉 This material is generally used to make sutures, textile mesh, tissue engineered scaffolds…

The PLGA 85:15 Filament

PLGA 85:15 Poly (Lactic-co-Glycolic acid) is a transparent and slightly golden amorphous thermoplastic. It degrades between 12 to 24 months once implanted. The polymer is quite rigid because at room temperature it is above the glass transition.

👉 This material is generally used for bone implants and tissue engineering. It can be mixed with hydroxyapatite or beta-TCP.

The PLA/PCL 70:30 Filament

PLCL 70:30 or Poly (Lactic acid-co-caprolactone) is a semi-crystalline, semi-transparent thermoplastic and has a slightly white appearance. It degrades between 12 to 24 months once implanted. The polymer has a glass transition temperature close to room temperature, which guarantees it great flexibility even though it is semi-crystalline.

👉 Thus, this material is generally used to make parietal reinforcements, guides for nerve reconstruction.

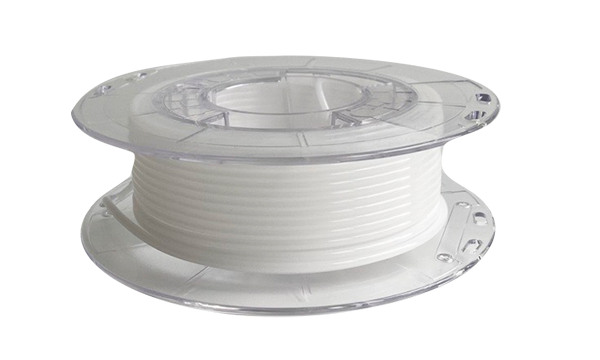

NEW! The PCL 100 filament

PCL or Caprolactone is a white, flexible, semi-crystalline thermoplastic. Once implanted, it degrades slowly over 36 months. The polymer has a glass transition temperature below room temperature, which ensures a certain degree of softness and flexibility.

👉 This material is widely used to make scaffolds for tissue engineering, osteosynthesis plates and screws, and sutures.

Our 3D Medical Filaments

The ABS Filament

Acrylonitrile Butadiene Styrene is an amorphous ivory-colored thermoplastic, durable and rigid. ABS is derived from granules complying with ISO 10993-5 certification for skin contact making it possible to make 3D parts…

👉…such as surgical planning models or prototypes of housing and interfaces in contact with the skin for patient monitoring.

The PC Filament

Polycarbonate is an amorphous thermoplastic known for its very high strength and resistance to high temperatures. The PC filament is made from granules complying with ISO 10993-5 certification for skin contact, it is also autoclavable and can be used in the operating room for guided surgeries.

👉 This filament is generally used for printing 3D parts such as surgical guides and cutting guides or medical instruments.

The PETG Filament

Polyethylene glycol is an amorphous and rigid thermoplastic. PETG is valued for its ease of use as well as its chemical resistance. The PETG filament is made from granules complying with ISO 10993-5 certification for skin contact.

👉It can be used to make prototypes of medical device packaging or prototypes of MD in contact with fluids (respirators, breathing duct, suction…).

The TPE Filament

Our thermoplastic elastomer filament is a white thermoplastic. With a glass transition temperature lower than room temperature, this thermoplastic is appreciated for its flexibility and high impact resistance. TPE filament is made from granules complying with ISO 10993-5 certification.

👉It is allowing skin contact applications such as orthopedic devices and flexible contact parts in interface with rigid parts of orthoses or prostheses.